In today’s fast-paced industrial landscape, speed, accuracy, and intelligent automation are no longer optional — they are essential. For manufacturers, packaging companies, and printing houses that work with cardboard and corrugated materials, the pressure to meet increasing demand while maintaining high-quality standards has never been greater. Enter the next generation of cutting technology: the CNC corrugated cardboard cutter.

This article explores how this powerful machine is transforming industries around the world. If you’re looking to elevate your packaging operations with a smart, fast, and accurate solution, it’s time to discover the full potential of CNC corrugated cutting.

What Makes It "Smart"?

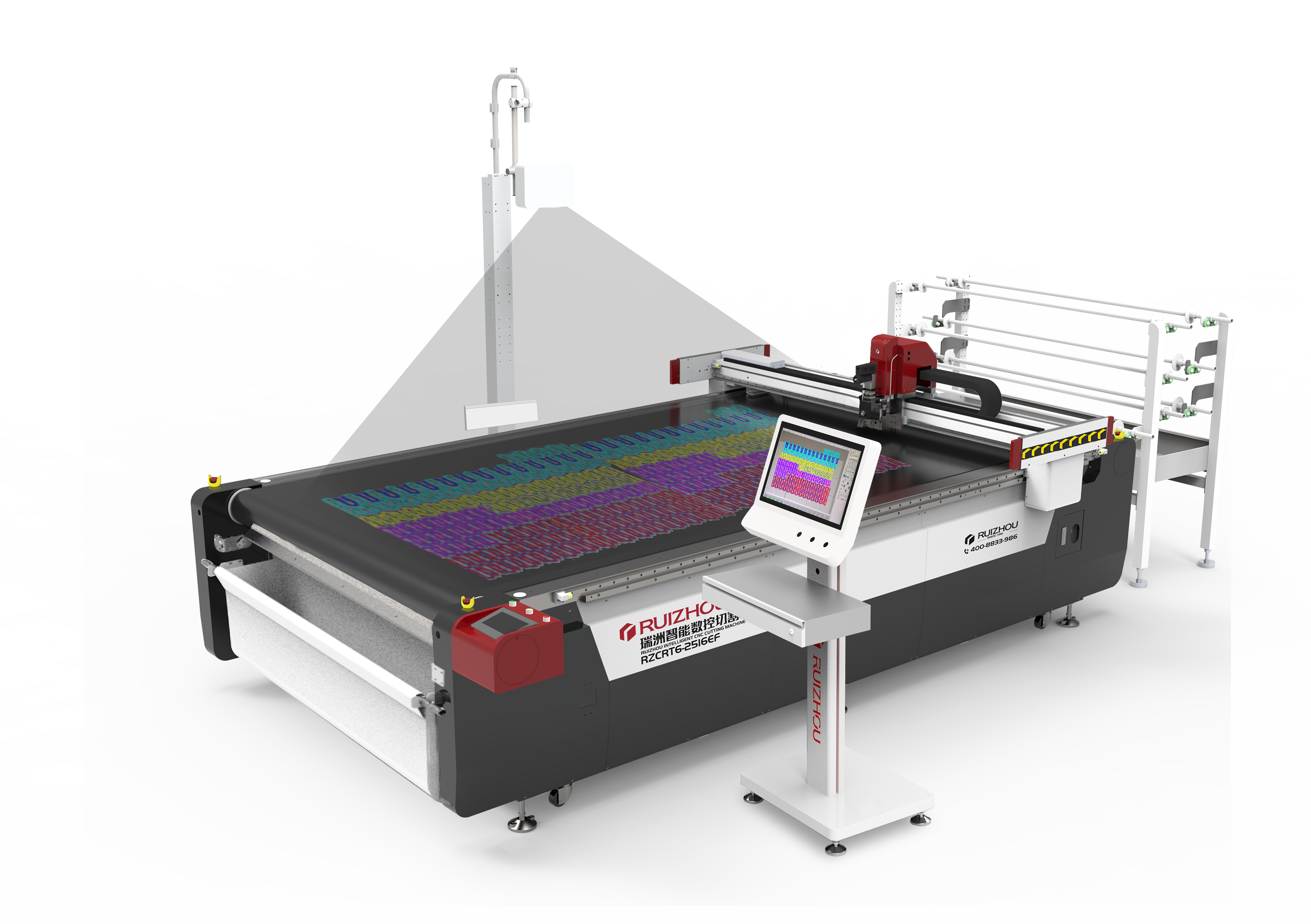

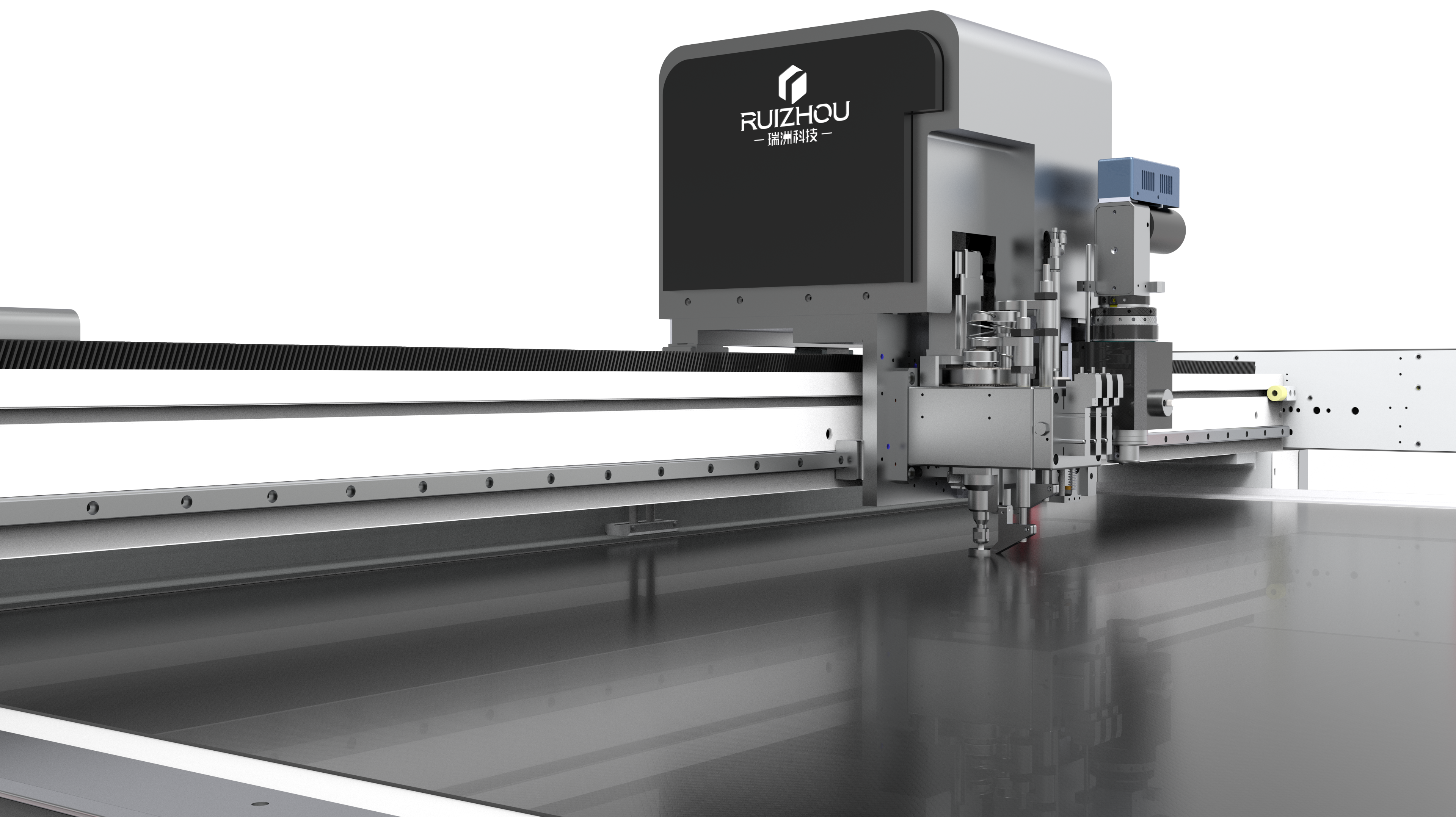

What Makes It "Smart"?Modern CNC corrugated cardboard cutters are equipped with intelligent control systems and intuitive interfaces. They read digital design files directly, eliminating the need for physical dies or molds. This not only saves time but also opens the door for on-demand customization.

AI-based algorithms optimize cutting paths automatically to reduce material waste, while smart sensors detect material thickness, adjust blade pressure in real time, and monitor wear — ensuring consistent cut quality and maximum machine life

Fast Matters – Speed Without Compromise

Time is money, especially in high-volume production environments. A top-tier packaging cutting machine can dramatically reduce turnaround times by processing multiple layers or sheets at once, while still maintaining precise alignment.

Compared to traditional die-cutting or manual methods, a CNC corrugated cardboard cutter can boost throughput by up to 60%, helping your business fulfill more orders in less time — without compromising on detail or quality.

Precision to the Millimeter

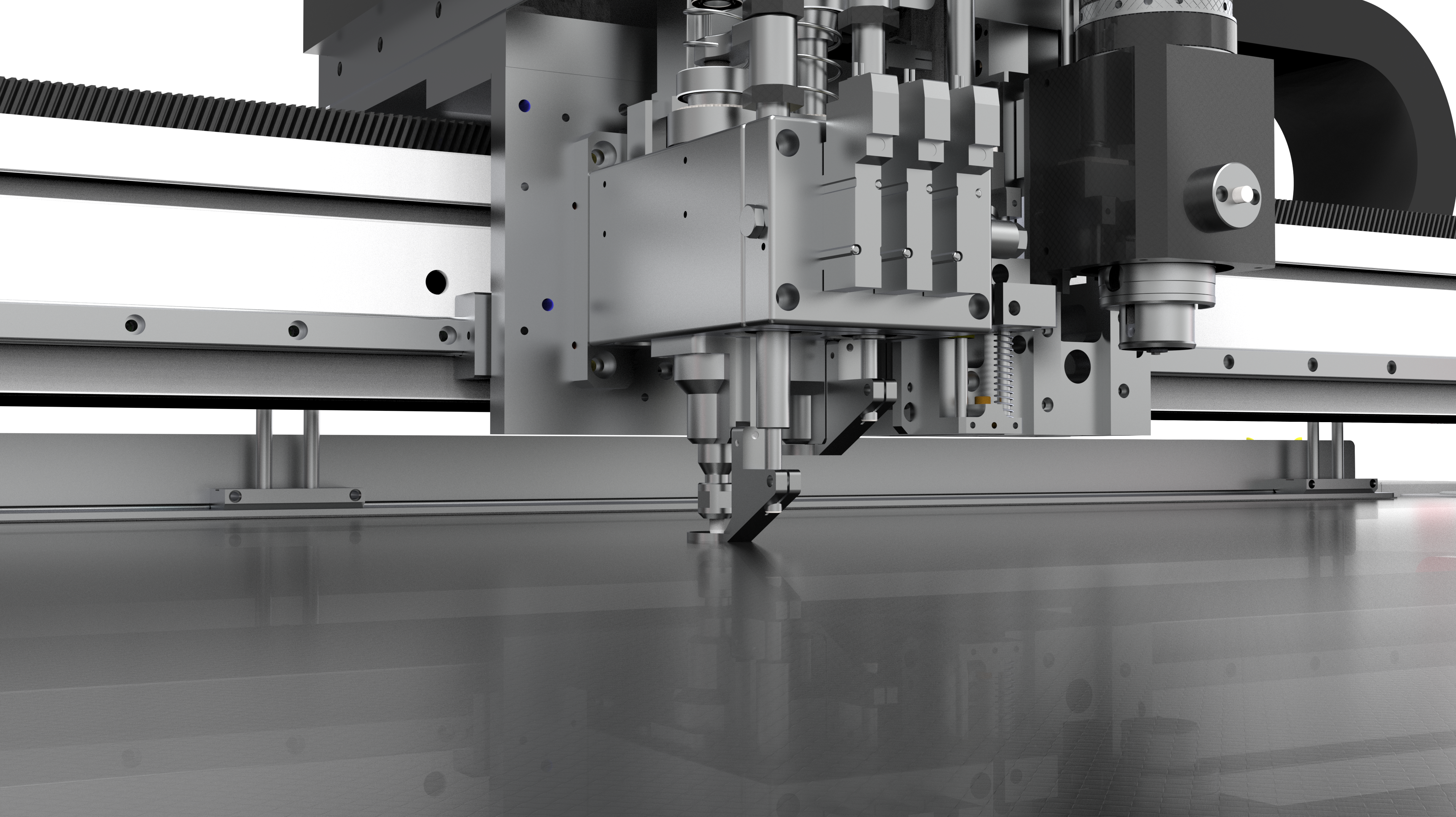

In industries where every millimeter counts, accuracy is critical. Whether you're cutting protective inserts, custom cartons, display stands, or retail packaging, precision affects both functionality and aesthetics.Thanks to high-speed servo motors, vision alignment systems, and rigid blade holders, today’s corrugated paper cutting machines achieve stunning detail and edge definition. You can expect consistent accuracy across thousands of cuts, even with challenging materials or complex contours.

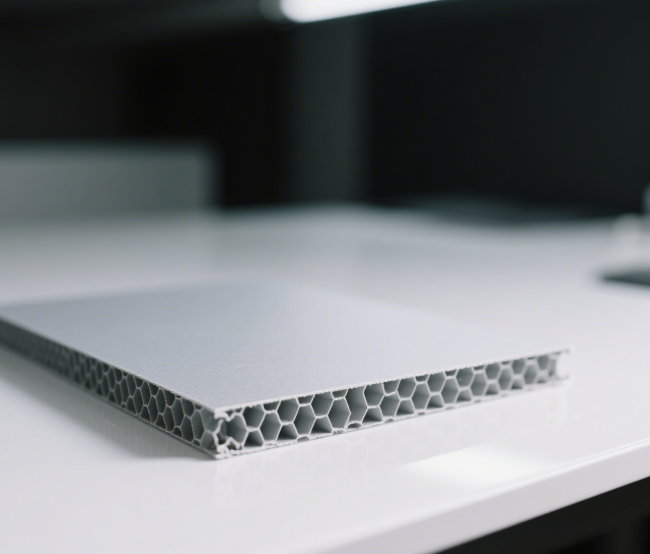

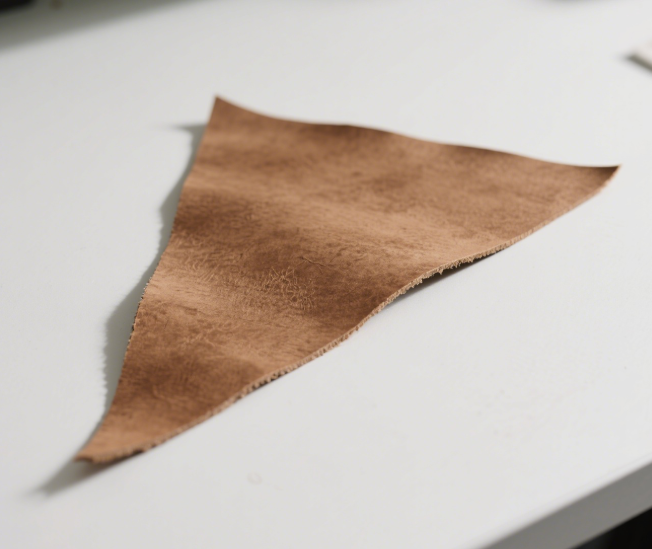

One of the greatest strengths of a carton cutting machine is its ability to work across a wide range of materials and applications. It’s not just for corrugated cardboard — these machines also handle honeycomb board, gray board, foam board, kraft paper, and more.

This makes the CNC cardboard cutter ideal for packaging companies, furniture brands, automotive parts suppliers, and display design studios — essentially any business that relies on customized structural design.

Cost Savings Beyond the Machine

While the initial investment in a CNC corrugated cardboard cutter may seem high compared to manual or basic equipment, the long-term savings are substantial. Here’s how:

Reduced material waste thanks to optimized cutting paths.

Lower labor costs through automation.

Faster prototyping without the need for physical dies.

Minimal maintenance due to smart system diagnostics.

Scalable production for both small-batch and high-volume runs.

The result? Faster ROI and a leaner, more agile production environment.

Choosing the Right CNC Corrugated Cutter

Not all cutters are created equal. When selecting a corrugated paper cutting machine, here are key factors to consider:

Cutting size and bed area — Does it match your material dimensions?

Cutting speed and acceleration — Can it keep up with your production needs?

Blade compatibility — Does it support drag knives, oscillating blades, and creasing tools?

Software integration — Is it compatible with your existing design workflow?

After-sales support — Will you get the training and technical help you need?

A reliable CNC cardboard cutter should not only meet today’s needs but grow with your business into the future.

As the demand for eco-friendly packaging, short-run production, and custom structures grows, investing in a smart, fast, and accurate CNC corrugated cardboard cutter is no longer a luxury — it’s a strategic move.With intelligent automation, scalable production capacity, and unmatched precision, this machine is not just a tool — it’s a competitive edge.

If your business is ready to leave behind outdated cutting methods and embrace a smarter future, there’s no better time to explore the power of CNC corrugated cutting. Whether you need a reliable packaging cutting machine, a high-speed carton cutting machine, or a multi-purpose corrugated paper cutting machine, today’s CNC cardboard cutters offer the performance, reliability, and innovation to take your production to the next level.