In today’s competitive manufacturing landscape, precision and speed are no longer optional—they are essential drivers of efficiency, quality control, and long-term profitability. Fabric manufacturers across multiple industries are under increasing pressure to shorten delivery cycles, reduce material waste, and maintain consistent output. To meet these demands, upgrading to an intelligent automatic fabric cutting machine has become a strategic decision rather than a simple equipment replacement.This advanced solution is designed specifically for industrial fabric processing, combining intelligent control systems with stable mechanical performance. As a professional cutting machine for fabric, it replaces traditional manual cutting methods with automated precision, enabling manufacturers to standardize production while significantly improving overall efficiency. By integrating digital control with industrial-grade components, the machine supports modern factories seeking higher productivity and predictable output.

1

Intelligent CNC Control for Consistent Cutting Accuracy

At the core of this system lies a high-performance Cnc cutting machine architecture. Digital control technology ensures that every cutting path strictly follows programmed data, eliminating inconsistencies caused by manual operation. This level of control allows manufacturers to maintain uniform cutting quality across repeated production runs, which is critical for large-volume and export-oriented orders.The equipment performs efficiently as a plain fabric cutting machine, ensuring smooth material feeding and accurate alignment during the cutting process. Flat fabric layouts are processed with exceptional stability, producing clean edges and precise dimensions while minimizing fabric deformation. As a result, material utilization is significantly improved, helping manufacturers reduce waste and control production costs.

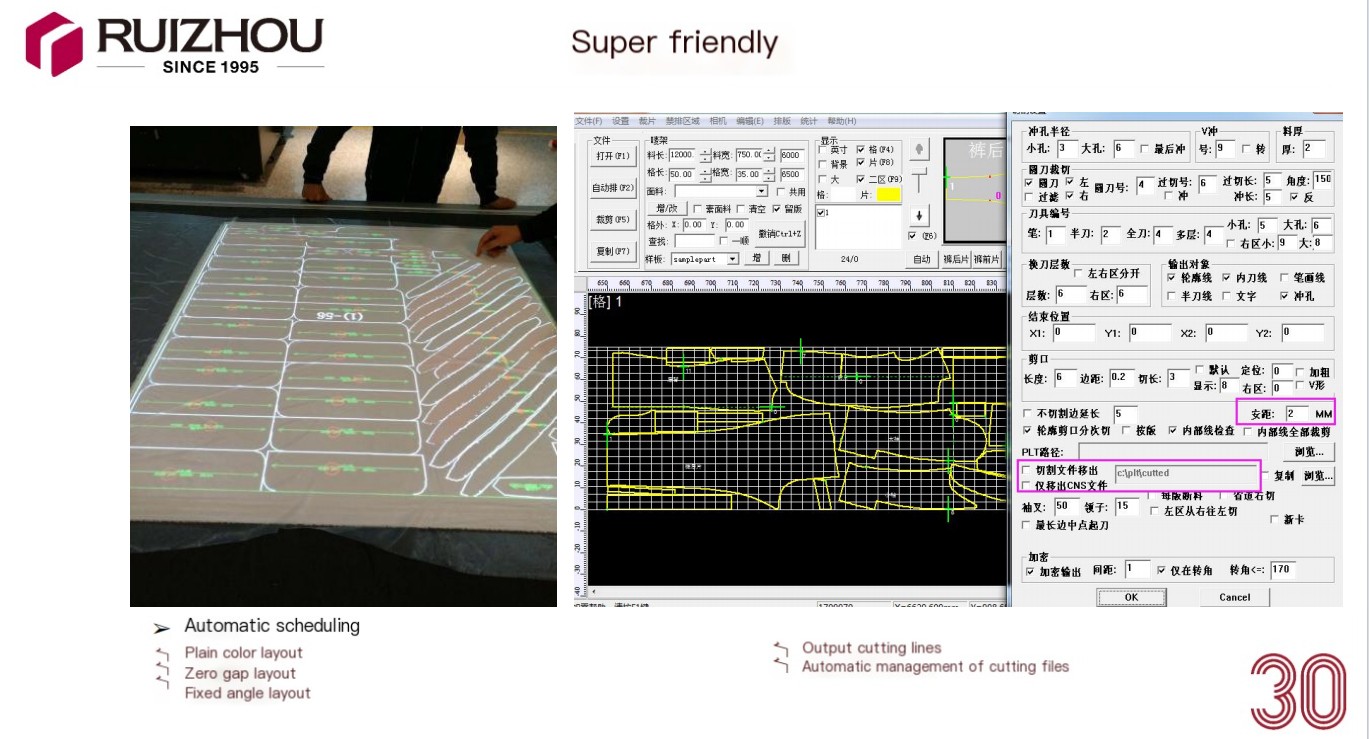

Intelligent software further enhances operational efficiency. Operators can manage cutting tasks through a user-friendly interface, reducing training time and minimizing reliance on highly skilled manual labor. Complex patterns and layered cutting tasks can be completed accurately, ensuring that the automatic fabric cutting machine delivers reliable results even in demanding production environments.

Industrial Reliability for Continuous Production

Built for long-term industrial use, this equipment functions as a durable and reliable cloth cutting machine. Its reinforced mechanical structure supports high-speed operation while maintaining cutting precision, making it suitable for both small-batch customization and continuous mass production. Stability during extended operation ensures predictable output, which is essential for manufacturers managing tight delivery schedules and strict quality standards.

As an advanced cutting machine for fabric, the system significantly reduces dependence on manual processes. Automated cutting minimizes human error, enhances consistency, and improves workplace safety by reducing repetitive manual tasks. This allows factories to reallocate labor resources toward higher-value activities such as quality inspection, process optimization, and production planning.The flexibility of this solution further strengthens its industrial value. By supporting multiple cutting configurations, the automatic fabric cutting machine can process various fabric types and thicknesses without compromising accuracy. This adaptability enables manufacturers to respond quickly to changing market demands while maintaining stable production performance.

2

A Scalable Solution for Modern Fabric Manufacturing

In the context of smart manufacturing and digital transformation, adopting an advanced Cnc cutting machine solution represents a forward-looking investment. Automation not only increases cutting speed but also supports scalable growth, allowing manufacturers to expand capacity without proportionally increasing labor costs.

The system continues to perform reliably as a plain fabric cutting machine in applications where surface flatness and dimensional accuracy are critical. Consistent cutting quality helps manufacturers meet strict customer requirements and international standards, strengthening competitiveness in global markets.

More than just a cloth cutting machine, this solution delivers measurable value across the entire production process. From reducing material waste and labor intensity to improving delivery reliability and product consistency, it supports sustainable manufacturing goals and long-term operational stability.

For manufacturers seeking precision, speed, and reliability in fabric processing, this automatic fabric cutting machine offers a practical and future-ready solution. To learn more about this product and explore professional fabric cutting solutions, please visit the official website:www.ruizhoutech.com