In leather production, the choice between manual cutting and automated solutions can significantly affect efficiency, quality, and profitability. Traditional hand cutting has been widely used in workshops, artisan factories, and small-scale production. While it allows for hands-on control, manual cutting often results in inconsistent edges, slower production speeds, higher labor costs, and material waste. Even highly skilled operators can struggle to maintain precision, especially with complex patterns or multi-layer designs.An automatic leather cutting machine transforms production by delivering consistent, precise, and high-speed results. With advanced computer-controlled systems, a CNC leather cutting machine ensures repeatable accuracy, minimizes errors, and optimizes material usage. This difference is crucial for manufacturers who need both quality and efficiency to stay competitive.

Efficiency and Precision

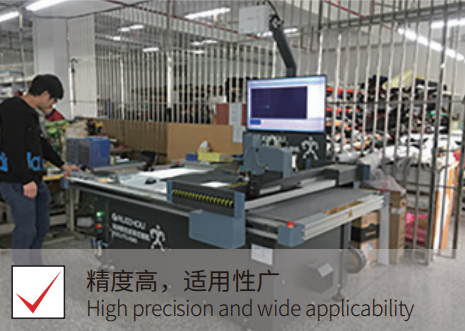

One of the most noticeable advantages of an automatic leather cutting machine is its efficiency. While manual cutting may take hours to produce a batch of leather pieces, a CNC system completes the same task in minutes. Modern leather cutting machines use intelligent nesting algorithms to maximize material usage, reducing waste and cost.The precision of a CNC leather cutting machine allows for perfect edges, clean cuts, and consistent results across all pieces. When paired with a custom leather die cutter, even intricate logos, patterns, and perforations can be accurately reproduced, which would be extremely challenging with manual methods. This combination ensures that manufacturers can maintain high-quality standards while dramatically improving output.

Automation also significantly lowers labor costs. Operators no longer need to perform repetitive cutting tasks, which reduces fatigue and the likelihood of errors. A CNC leather cutting machine can cut multiple layers simultaneously, maintaining uniformity and saving substantial production time. By replacing manual labor with automated cutting, businesses can redirect staff to quality control, machine supervision, or other value-added tasks, increasing overall productivity.

Customization and Versatility

For companies producing custom leather goods, a custom leather die cutter integrated with an automatic leather cutting machine is invaluable. Complex shapes, curves, and perforations can be produced effortlessly, ensuring high accuracy and repeatability. This capability is impossible to achieve consistently with hand cutting. Additionally, a leather cutting machine can handle different leather types and thicknesses, from soft lambskin to firm cowhide, providing versatile solutions for a wide range of products such as handbags, shoes, belts, and automotive interiors.

Manual cutting is inherently limited by operator skill and endurance, but automated cutting offers remarkable scalability. Factories equipped with a CNC leather cutting machine can produce hundreds of identical pieces in the time a manual worker cuts only a few. For businesses looking to scale operations, enter new markets, or fulfill large orders efficiently, this level of automation is essential. High-volume production becomes feasible without compromising quality, which gives manufacturers a competitive edge.

Safety and Workplace Improvement

Safety is another major benefit of automation. Hand cutting with knives or rotary tools carries a significant risk of injury. Using an automatic leather cutting machine reduces operator exposure to hazards and creates a safer working environment. Safer workplaces contribute to lower insurance costs and higher employee satisfaction, as staff can focus on supervising machines and ensuring quality rather than performing repetitive, high-risk manual tasks.Modern CNC leather cutting machines are designed for long-term reliability. They require minimal maintenance, and software updates can improve efficiency and add new cutting functions. Investing in an automatic leather cutting machine is not just a productivity upgrade—it is a long-term strategy for consistent quality and reduced operational risk. Over time, businesses benefit from lower labor costs, less material waste, and higher production output, all while maintaining professional-grade results.

HOW TO CONTACT US

The difference between manual cutting and automated cutting is substantial. Manual methods rely on human skill but are slow, inconsistent, and labor-intensive. In contrast, an automatic leather cutting machine, especially when paired with a custom leather die cutter or used as a CNC leather cutting machine, delivers unmatched precision, efficiency, and scalability. For modern leather manufacturers aiming to reduce waste, increase production, and achieve consistent high-quality results, investing in automation is no longer optional—it is essential. A leather cutting machine transforms operations, enhances product quality, and empowers businesses to remain competitive in today’s fast-paced leather industry.

💡 Contact us today at www.ruizhoutech.com to learn more about our automatic leather cutting machines and get a personalized solution for your business!