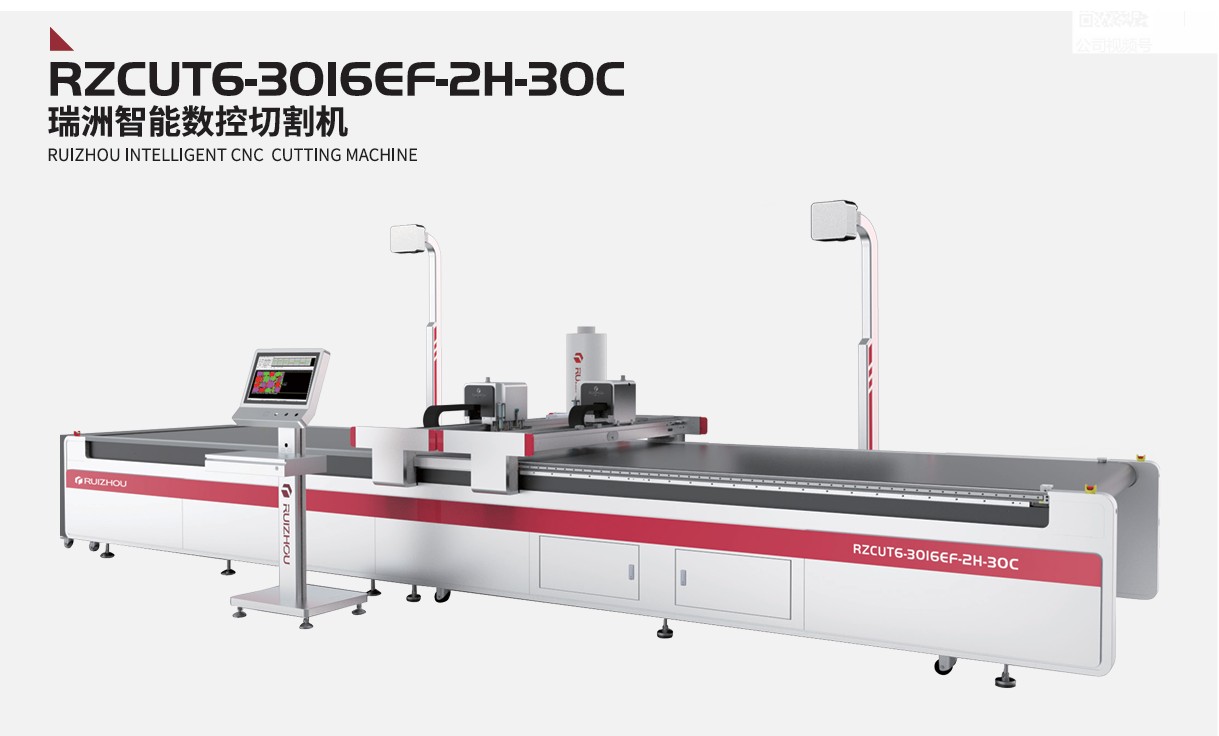

When businesses ask, “What can you do with a cutting machine?”, the answer often depends on the type of machine you choose. In the leather industry, precision, consistency, and efficiency are critical factors that separate average production from world-class results. That is why many professionals rely on the automatic leather cutting machine, a solution engineered to transform how leather products are designed, cut, and manufactured.

Unlike traditional manual methods, this advanced leather cutting machine integrates intelligent software, high-speed cutting tools, and durable industrial construction to handle everything from soft leather sheets to thicker, multi-layered materials. It delivers clean, accurate cuts without fraying, making it an ideal choice for manufacturers in footwear, bags, furniture, automotive interiors, and more.

Why Choose an Automatic Leather Cutting Machine?

The automatic leather cutting machine is designed to simplify complex tasks while maintaining maximum efficiency. Its automated feeding system, combined with AI nesting software, reduces material waste and optimizes each sheet of leather. Instead of relying on skilled manual labor that can be slow and inconsistent, this cutting machine guarantees repeatable precision on every project.

For industries where time equals profit, automation is the key. This machine allows you to cut multiple patterns within minutes, significantly reducing turnaround time. Whether you are producing luxury handbags, durable car seat covers, or high-performance sports gear, the machine ensures your designs are replicated with flawless accuracy.

At the core of this solution is CNC (Computer Numerical Control) technology. A leather CNC cutting machine operates through pre-programmed designs, ensuring that every cut matches the digital blueprint perfectly. No matter how intricate the pattern is, CNC control guarantees consistency.

This is especially valuable for brands that need to maintain strict quality control. A single mistake in cutting can lead to wasted leather, lost time, and higher costs. With a leather CNC cutting machine, errors are minimized, and precision is maximized, allowing companies to deliver top-quality products to their customers.

Understanding Leather Cutting Machine Price

For many buyers, the first question after exploring the machine’s features is about cost. The leather cutting machine price may vary depending on configuration, size, and additional features like double-head cutting or conveyor systems. While the initial investment may seem significant compared to manual tools, the long-term value far outweighs the cost.Here’s why:

When factoring these benefits, the leather cutting machine price becomes an investment that pays itself back quickly through efficiency and profitability.

For factories and enterprises handling high production volumes, the industrial leather cutting machine is the ultimate solution. Built with robust frames, powerful motors, and long-lasting components, it is engineered to run continuously in demanding environments.This type of machine is not limited to small workshops. It is widely used in large-scale operations where thousands of leather pieces must be cut daily. Its durability ensures minimal downtime, while its intelligent system allows operators to manage complex orders without delays.The industrial leather cutting machine supports various cutting tools such as oscillating knives, punching tools, and creasing tools. This versatility allows manufacturers to expand their product range and meet diverse market demands without needing multiple machines.

Applications Across Industries

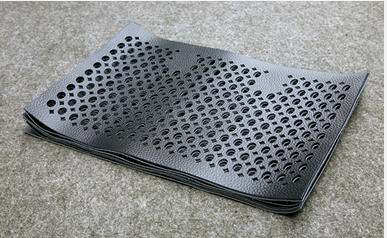

What can you do with a cutting machine like this? The possibilities are vast:

Footwear: Cut soles, uppers, and insoles with consistent sizing.

Bags & Luggage: Create precise panels for handbags, backpacks, and suitcases.

Automotive: Cut seat covers, floor mats, and dashboards with durability.

Furniture: Shape leather upholstery for sofas, chairs, and custom interiors.

Fashion Accessories: Produce belts, wallets, and straps with clean edges.

With just one automatic leather cutting machine, businesses can diversify their offerings, streamline production, and deliver higher quality products faster than ever before.

There are many cutting machines on the market, but not all are created equal. The combination of CNC technology, automatic feeding, and industrial durability makes this machine stand out. It eliminates human error, boosts productivity, and ensures that every piece of leather is utilized to its maximum potential.The machine is designed with user-friendly controls. Even beginners can learn to operate it quickly, while experienced operators can unlock advanced features for more complex production.

Upgrade Your Production Today

To answer the question, “What can you do with a cutting machine?” — with the right technology, you can do everything. The automatic leather cutting machine is not just a tool; it is a complete production solution that improves accuracy, reduces costs, and scales with your business.Whether you are a small workshop looking to boost efficiency or a global manufacturer seeking an industrial leather cutting machine to meet growing demand, this machine offers the reliability and performance you need.

👉 Contact us today to learn more about the leather cutting machine price and discover how this leather CNC cutting machine can transform your leather production line. Efficiency, precision, and profitability are only one step away.www.ruizhoutech.com