How RUIZHOU Intelligent Cutting Technology Is Reshaping the Global Bag Manufacturing Industry

As global demand for bags and luggage continues rising, manufacturers are facing unprecedented production pressure. Large order volumes, shorter delivery cycles, rapidly changing styles, high material costs, and increasing labor expenses have become common industry challenges. In this new environment, factories urgently need cutting systems that deliver higher stability, lower operating costs, and greater flexibility to handle diverse materials and multiple order types.In response to these fast-evolving market needs, RUIZHOU has launched its next-generation bag cutting machine, along with an upgraded automatic bag cutting machine series designed specifically for high-speed, precise, and stable cutting of flexible materials in bag and luggage production. Backed by more than 20 years of innovation and industrial expertise, and built upon RUIZHOU’s mature and reliable cnc cutting machine platform, the new product line offers global manufacturers a smarter way to enhance output capacity, cost efficiency, and digital production readiness.

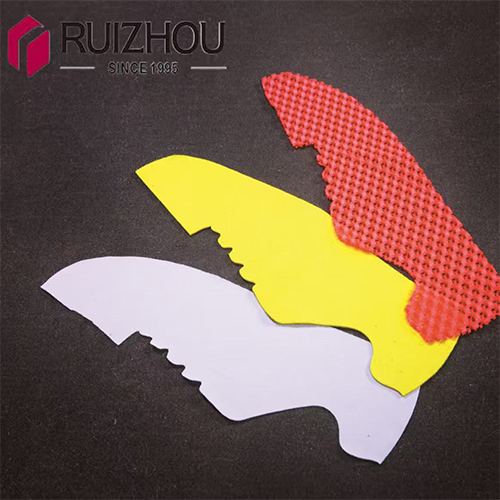

As a leading bag cutting machine factory, RUIZHOU integrates advanced hardware engineering with intelligent software algorithms to bring factories a fully digital, automated cutting solution capable of processing nylon, canvas, composite fabrics, PU, TPU, and many more flexible materials. The upgraded nylon bag cutting machine achieves breakthroughs in cutting accuracy, speed, and material utilization, redefining production standards for modern bag factories.

Luggage bag indust

Luggage bag industry

Luggage bag industry

1

Enabling the Transition From Traditional Cutting to Digital, Flexible Manufacturing

Traditional bag manufacturing relies heavily on manual cutting. Human-dependent nesting, inconsistent accuracy, unstable cut quality, and high waste rates work against factories striving for efficiency and precision. These limitations become more apparent as product complexity increases and market cycles accelerate. RUIZHOU’s new-generation bag cutting machine directly addresses these pain points and provides a future-ready solution.

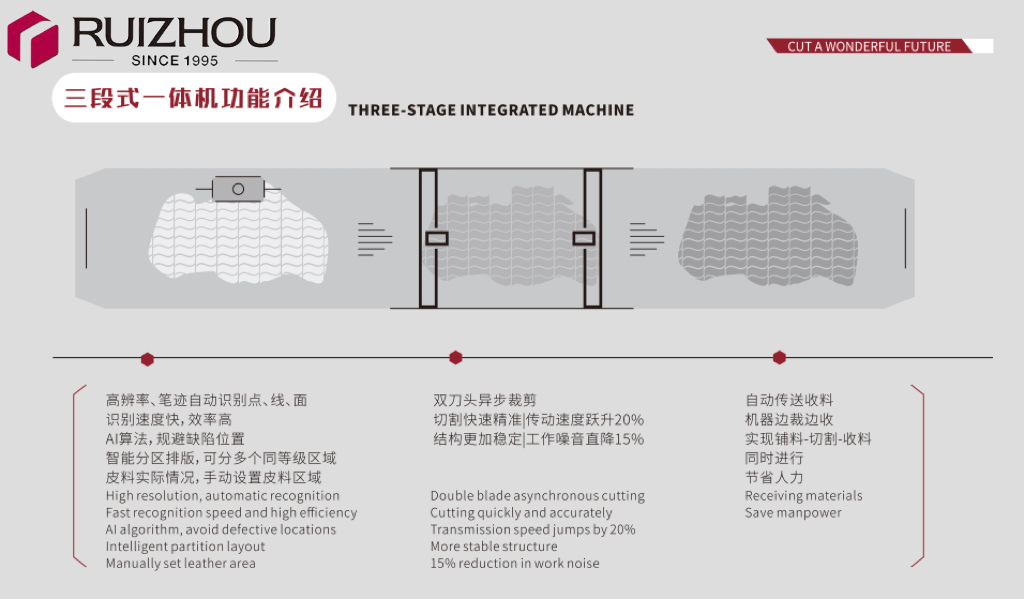

The system integrates HD industrial cameras and automated recognition technology to scan material texture, contour, defects, and deformation. It automatically adjusts cutting depth, knife speed, and vacuum pressure according to fabric characteristics, ensuring smooth, accurate, and stable cutting—even on soft TPU layers, multi-layer nylon composites, or thin apparel fabrics.To maximize material utilization, RUIZHOU’s intelligent nesting engine automatically generates optimized layouts for large fabric surfaces. Compared to manual nesting, factories can save 5% to 15% of material depending on fabric type. With material costs rising globally, this level of efficiency delivers significant profitability gains for manufacturers.

Through modular equipment design and AI-driven algorithms, RUIZHOU enables factories to switch between materials and styles with minimal adjustment time. This agility is critical for handling diverse small-batch or customized orders, helping manufacturers shorten lead times and strengthen competitive responsiveness.

Why More Bag Factories Are Choosing RUIZHOU

As the bag and luggage industry evolves from “durability” to “personalization, high functionality, and premium quality,” product designs have become more sophisticated. More components, more stitching lines, tighter tolerances, and new material combinations drive the need for far more accurate and versatile cutting systems.RUIZHOU’s intelligent nylon bag cutting machine is equipped with high-precision servo control and a rigid motion platform that ensures extremely low cutting deviation. It handles complex curves, shoulder straps, inner linings, EVA foam layers, and multi-layer composites with consistent accuracy. Bulk data import and fast toolpath generation allow factories to adapt quickly to new product styles and significantly shorten new-product launch cycles.For multi-material production environments, RUIZHOU’s modular tool system supports oscillating knives, circular knives, punching tools, creasing tools, and more. This makes the machine highly compatible with travel luggage, sports bags, outdoor packs, school bags, leather goods, and other categories.In nylon cutting applications in particular, the machine’s high-frequency oscillation and precision knife-path control prevent fraying, melting, stretching, or distortion. For brands targeting high-end product quality, this technology dramatically improves both the appearance and structural integrity of the final product.

Built upon the mature RUIZHOU cnc cutting machine architecture, the system provides an integrated digital workflow that includes automatic scanning, automatic nesting, intelligent cutting, real-time monitoring, and production traceability. This enables factories to gain full visibility into their processes and operate with higher efficiency, consistency, and quality control.

1

RUIZHOU Is Driving the Future of Bag Manufacturing

Automation and digitalization are no longer optional upgrades; they are the foundation of future competitiveness. As global supply chains shift and manufacturing accelerates its transformation, bag factories are moving rapidly from labor-driven workflows toward intelligent production. RUIZHOU’s bag cutting machine and automatic bag cutting machine serve as core equipment in this transition, helping manufacturers unlock higher productivity, lower costs, and stronger market resilience.From material savings to improved cut accuracy, from reduced labor dependence to enhanced flexibility for multi-variant production, RUIZHOU is empowering global bag and luggage manufacturers to move from traditional manufacturing to high-efficiency, intelligent production.Looking ahead, RUIZHOU will continue integrating AI algorithms, smarter sensors, and advanced automation technologies to build future-ready cutting ecosystems for the bag industry. As personalization and small-batch diversity continue to expand, RUIZHOU’s intelligent cutting systems will become essential tools for factories seeking faster, leaner, and more stable production capabilities.

RUIZHOU remains committed to becoming the most trusted global partner for intelligent bag manufacturing in the digital era.Company Website:www.ruizhoutech.com