At the 28th Wenzhou Shoe Material & Machinery Fair, scheduled for August 22–24, 2025, at the Wenzhou International Convention and Exhibition Center, RUIZHOU Technology is proud to present four of its most advanced innovations in leather cutting. As a pioneer with over 30 years of expertise in digital cutting technology, RUIZHOU will highlight how its intelligent leather cutting machine, cnc leather cutter, and automatic leather cutting machine can help footwear and leather goods manufacturers achieve unmatched precision, cost savings, and efficiency.

The global leather goods and footwear industry has entered a new era where intelligent automation is no longer optional but essential. Manufacturers face rising labor costs, fluctuating raw material prices, and the demand for fast, customized production. To address these challenges, RUIZHOU is unveiling its new generation of shoe material cutting machine, built on a platform of innovation, reliability, and productivity. Visitors at Booth 6A177 will have the opportunity to see real-time demonstrations of how these cutting-edge solutions empower companies to boost efficiency, reduce waste, and elevate product quality.

Intelligent Leather Cutting: A Game Changer

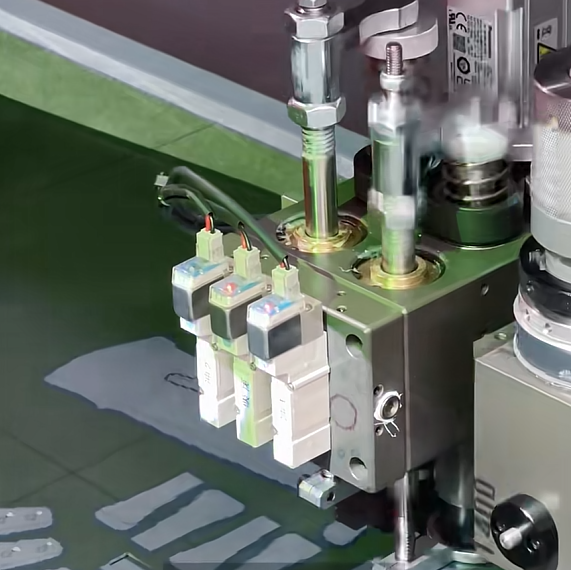

The intelligent leather cutting machine by RUIZHOU is engineered to meet the growing demand for automation in shoe and bag production. With integrated nesting software, the system optimizes material utilization, ensuring minimal leather waste. It is equipped with smart vision recognition to detect flaws and patterns on natural hides, making it an essential tool for factories that prioritize quality and sustainability. Compared to traditional manual cutting, RUIZHOU’s intelligent solutions reduce error rates dramatically and shorten production cycles, allowing manufacturers to respond to market trends faster.

RUIZHOU’s cnc leather cutter has become a benchmark in the industry for its unmatched precision. The machine is capable of cutting intricate designs with accuracy down to 0.01mm, ensuring perfect results for high-end footwear and luxury leather products. Its versatility makes it suitable for a wide variety of materials, from natural hides to synthetic fabrics. With multi-tool heads and dual working tables, production lines can achieve continuous operation, significantly improving throughput and reducing downtime.

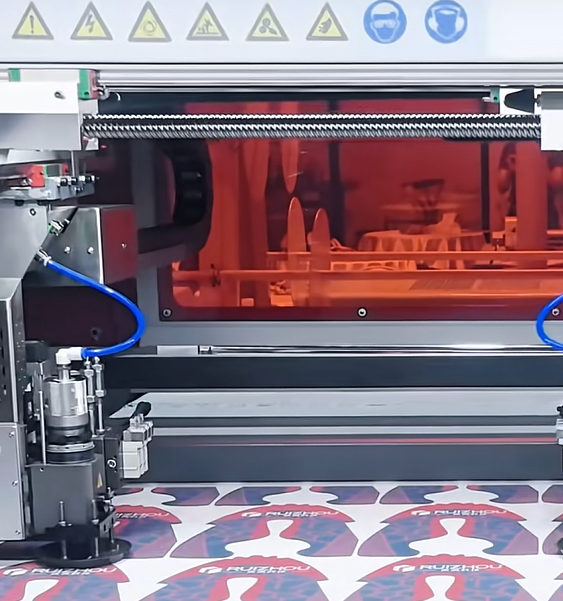

Automatic Leather Cutting Machine for Smart Factories

The automatic leather cutting machine is designed for large-scale operations seeking to modernize their production. Equipped with IoT connectivity and intelligent scheduling, it can be seamlessly integrated into smart factory systems. This innovation enables real-time monitoring, predictive maintenance, and fully automated workflows, allowing manufacturers to save labor costs and improve consistency. In a competitive industry where on-time delivery is crucial, the RUIZHOU automatic solution ensures reliable, around-the-clock performance.Footwear and leather goods companies are constantly under pressure to deliver customized designs quickly without compromising quality. The shoe material cutting machine by RUIZHOU answers this need. With digital templates and automated nesting, manufacturers can quickly adapt to small-batch production runs or large orders with equal efficiency. This flexibility makes the machine ideal for both established brands and emerging startups who want to compete in fast-paced markets.

Beyond individual machines, RUIZHOU positions itself as a provider of comprehensive smart cnc cutting solutions. Its ecosystem includes software, hardware, after-sales support, and training services. By integrating big data and AI algorithms, RUIZHOU ensures that its machines learn and improve with every cut. This empowers businesses to maintain a competitive edge, especially in international markets where speed, accuracy, and customization are key success factors.

While RUIZHOU’s solutions are widely recognized in the shoe industry, their applications extend beyond footwear into leather goods, automotive interiors, furniture, apparel, and packaging. Many domestic manufacturers have already reported remarkable ROI after switching to RUIZHOU’s cutting systems. Customers consistently highlight improvements in productivity, significant material savings, and reduced dependency on skilled labor. These success stories are proof that RUIZHOU delivers not just machines but long-term value.

Commitment to Innovation and Service

RUIZHOU’s philosophy is to innovate continuously while delivering reliable support. With a modern manufacturing base in Foshan, China, the company invests heavily in R&D and quality assurance. Every cnc leather cutter and automatic leather cutting machine undergoes rigorous testing to guarantee performance. Moreover, RUIZHOU provides global technical support, online diagnostics, and on-site training to ensure clients maximize their investment.

The Wenzhou Shoe Material & Machinery Fair is the ideal platform for industry professionals to explore the latest advancements in digital cutting. RUIZHOU warmly invites all visitors to Booth 6A177 to experience firsthand how its intelligent leather cutting machine, cnc leather cutter, automatic leather cutting machine, shoe material cutting machine, and smart cnc cutting solutions can revolutionize production lines. With four groundbreaking models on display, RUIZHOU is ready to demonstrate its mission: helping manufacturers reduce costs, increase efficiency, and embrace the future of intelligent manufacturing.

For more information, please visit the official website: www.ruizhoutech.com