As the global Cloth Industry accelerates its transition toward automation, digitalization, and flexible manufacturing, fabric cutting has emerged as a decisive factor in improving productivity and controlling costs. Rising labor expenses, shrinking delivery cycles, and increasing demand for diversified apparel styles are forcing garment manufacturers to rethink traditional production models. In this transformation, advanced fabric cutting technology—centered on the cloth cutting machine—is redefining how modern apparel factories operate.

From Manual Cutting to CNC Automation

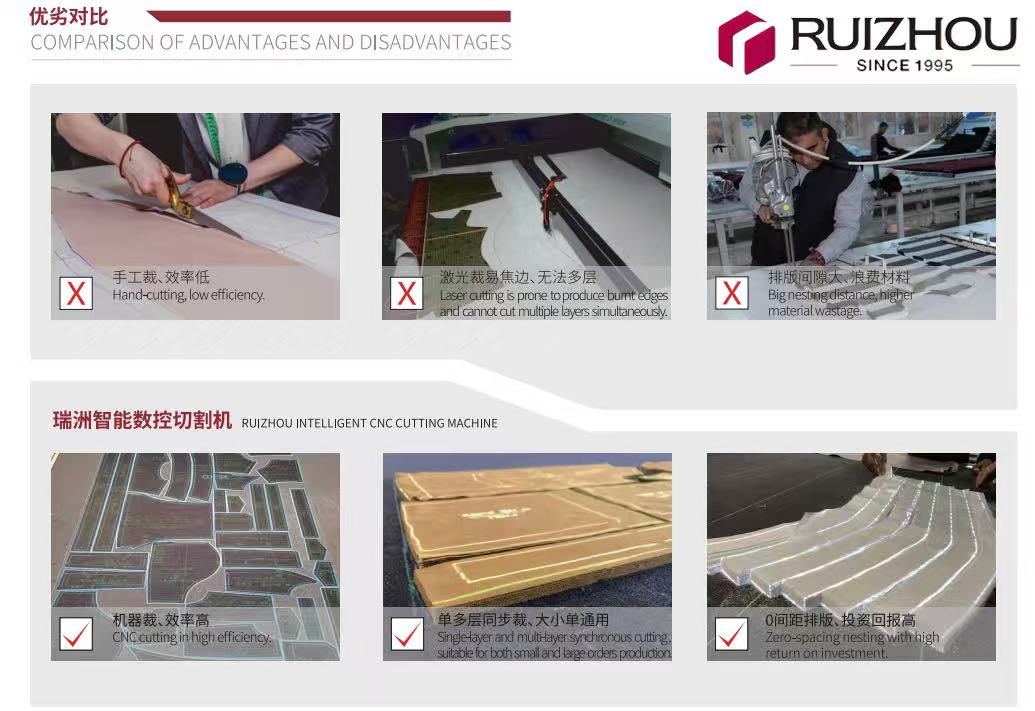

For decades, manual fabric cutting dominated garment production. While suitable for small-scale operations, this approach is highly dependent on skilled labor and prone to inconsistencies, material waste, and limited efficiency. As market competition intensifies, such limitations have become increasingly evident.The widespread adoption of the cnc fabric cutting machine marks a fundamental shift in the industry. By integrating digital pattern input, precision motion control, and automated cutting paths, CNC systems enable consistent, high-accuracy cutting regardless of order complexity. This transition from labor-driven processes to data-driven automation allows manufacturers to scale production while maintaining stable quality standards.

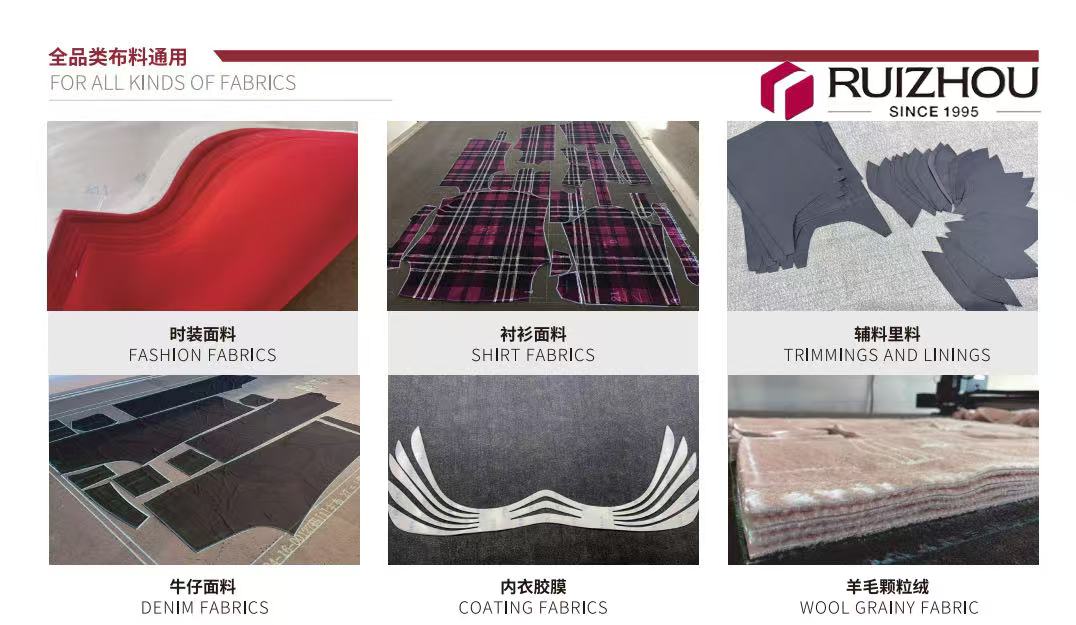

Today’s cutting machine for fabric is no longer a single-function tool. It has evolved into an integrated production system that combines automatic spreading, intelligent nesting, high-speed cutting, and production data management. By connecting with CAD and CAM software, factories can optimize fabric utilization before cutting even begins, significantly reducing material waste.This technological evolution is particularly valuable when handling diverse fabric types, including woven fabrics, knitted materials, elastic textiles, and functional composites. Advanced machines adjust cutting parameters automatically to ensure clean edges and dimensional accuracy, making them suitable for a wide range of garment applications—from fashion apparel to sportswear and industrial uniforms.When investing in new equipment, fabric cutting machine price is often one of the first considerations. However, experienced manufacturers increasingly recognize that upfront cost alone does not reflect true value. Lower-priced machines may reduce initial investment but often result in higher long-term expenses due to maintenance issues, unstable performance, or limited adaptability.In contrast, evaluating industrial fabric cutting machine price from a lifecycle perspective provides a more accurate picture. Factors such as cutting speed, durability, software compatibility, material savings, and after-sales support all contribute to the total return on investment. As a result, many apparel manufacturers are shifting their focus from short-term cost savings to long-term operational efficiency.

Industrial-Grade Cutting Machines Enable Scalable and Flexible Production

Industrial-grade cutting systems play a critical role in enabling both large-scale output and flexible production scheduling. Supported by robust hardware and intelligent control systems, modern machines can operate continuously under high workloads while maintaining precision.The value embedded in industrial fabric cutting machine price also lies in its ability to support data-driven manufacturing. Real-time monitoring of cutting efficiency, fabric consumption, and production output provides managers with actionable insights, allowing for better planning, reduced waste, and improved profitability. This combination of scale and flexibility has become a defining feature of competitive garment factories.

As a dedicated provider of intelligent cutting solutions, RUIZHOU has built a strong reputation in the apparel manufacturing sector. With a deep understanding of garment production workflows, RUIZHOU develops cutting systems that balance speed, precision, and long-term reliability.RUIZHOU’s garment cutting machines are designed to handle a wide variety of fabrics while ensuring consistent performance and high material utilization. By continuously refining control systems and mechanical structures, RUIZHOU helps apparel manufacturers reduce labor dependency, improve cutting accuracy, and adapt to rapidly changing market demands.Through tailored solutions and ongoing technological innovation, RUIZHOU supports garment factories at different stages of automation—from upgrading manual operations to building fully intelligent production lines.

Supporting Sustainable Growth in the Cloth Industry

As sustainability and efficiency become central themes in global manufacturing, intelligent fabric cutting technology is playing an increasingly important role. By minimizing material waste, optimizing energy use, and improving production consistency, advanced cutting systems help apparel manufacturers achieve both economic and environmental objectives.RUIZHOU remains committed to advancing intelligent cutting technology within the Cloth Industry, empowering manufacturers to achieve higher efficiency, lower costs, and sustainable growth.

To learn more about RUIZHOU’s garment industry cutting solutions, please visit the official website:www.ruizhoutech.com