Rezhou Tech Expo Showcases Cutting-Edge Innovations

The Rezhou Tech Expo, held in the heart of the technology hub, was a resounding success, attracting global industry leaders, manufacturers, and tech enthusiasts. The event was dedicated to showcasing the latest advancements in cutting-edge innovations, particularly in the realm of precision cutting technology. This year’s expo highlighted an impressive array of machines designed to revolutionize various industries, from fashion to automotive, providing solutions that enhance efficiency, precision, and automation.

One of the most significant areas of focus was the introduction of state-of-the-art Cloth Cutting Machines and Fabric Cutting Machines. These machines, equipped with advanced software and mechanical precision, have transformed the way fabric and textiles are processed. Offering high-speed cutting capabilities with minimal waste, these machines are essential for companies looking to streamline their production lines and reduce overhead costs. With fabric-cutting precision being vital in the garment industry, the expo featured machines that could handle everything from basic cuts to complex patterns, delivering results that were both fast and consistent.

In addition to fabric-based technologies, the expo also showcased a range of Precision Cutting Machines, which stand out for their ability to cut with an unprecedented level of accuracy. These machines are designed for industries that require ultra-fine tolerances, such as electronics, aerospace, and medical device manufacturing. Equipped with laser, water jet, and mechanical cutting capabilities, the precision cutting machines featured at the event could achieve levels of accuracy down to microns, making them ideal for high-tech applications that demand the utmost quality and performance.

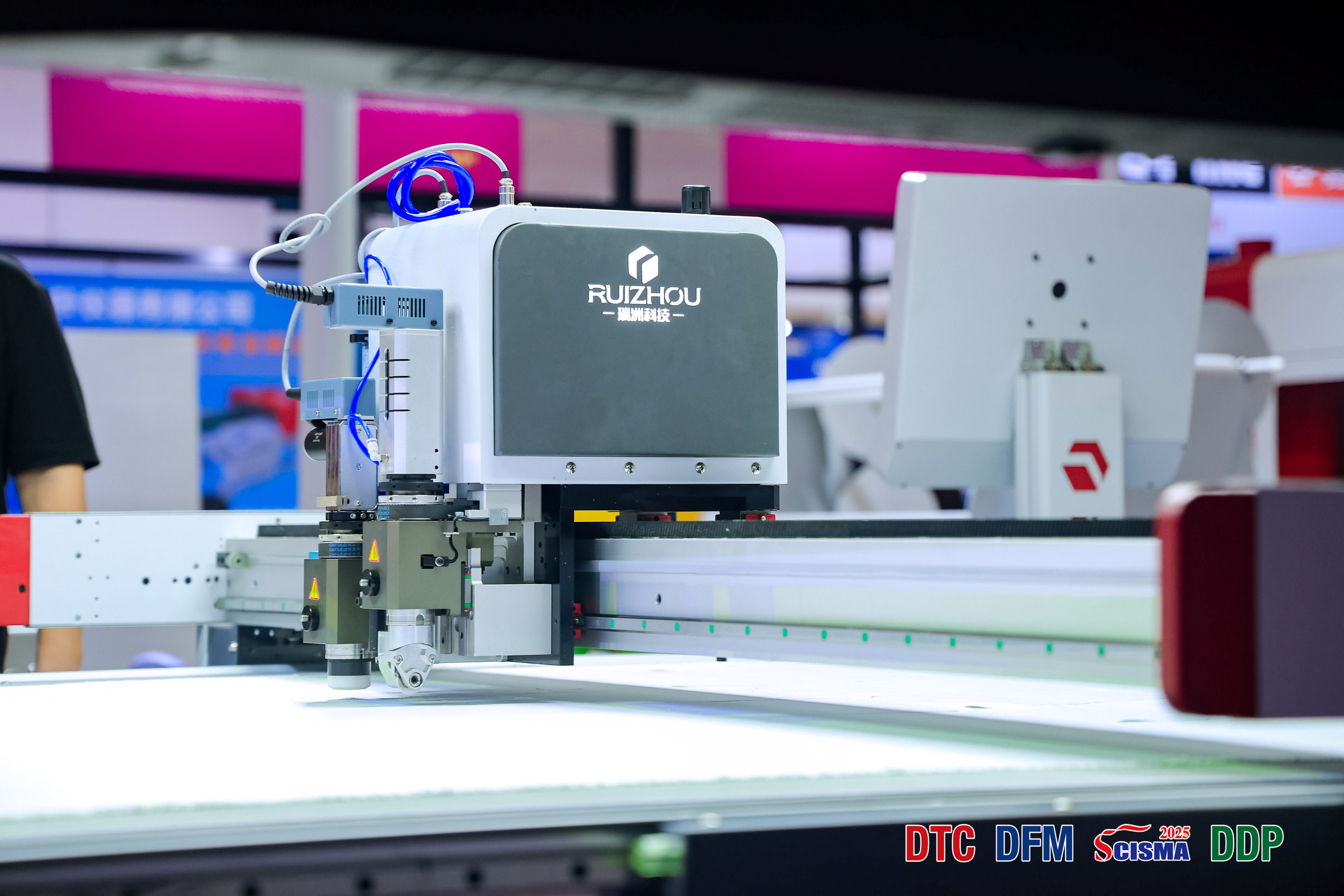

A highlight of the expo was the display of CNC Cutting Machines, which have become indispensable in modern manufacturing. CNC (Computer Numerical Control) technology allows machines to follow precise programmed instructions to cut materials with extreme accuracy. These machines are highly versatile and can be used in a wide range of applications, from metalworking to woodworking and plastics. The CNC machines featured at the Rezhou Tech Expo were particularly notable for their speed, reliability, and adaptability, offering solutions that improve both production times and quality control processes.

Equally impressive was the showcase of Leather Cutting Machines, which attracted significant attention due to their precision and versatility in working with tough materials like leather, rubber, and vinyl. Leather cutting requires specialized technology due to the material's unique properties, and the machines displayed at the event were designed to handle intricate cuts, whether for fashion, automotive interiors, or industrial applications. These cutting-edge leather machines provide enhanced speed and accuracy, making them an invaluable tool for businesses in the leather industry.

The Rezhou Tech Expo was not just a showcase of products; it was a gathering of minds, fostering collaboration between cutting machine manufacturers and industry experts. Throughout the event, attendees had the opportunity to engage in discussions about the latest trends in automation and machine technology, gaining insights into how these innovations are shaping the future of various sectors. The expo also featured live demonstrations, allowing visitors to witness the capabilities of these cutting-edge machines in real-time and understand how they can be integrated into existing production processes.

The Rezhou Tech Expo successfully demonstrated the incredible potential of modern cutting technologies, particularly through the introduction of Cloth Cutting Machines, Fabric Cutting Machines, Precision Cutting Machines, CNC Cutting Machines, and Leather Cutting Machines. The event provided a glimpse into the future of manufacturing, where automation, precision, and efficiency take center stage. As industries continue to evolve, these machines will undoubtedly play a crucial role in transforming production processes, reducing costs, and increasing overall product quality.