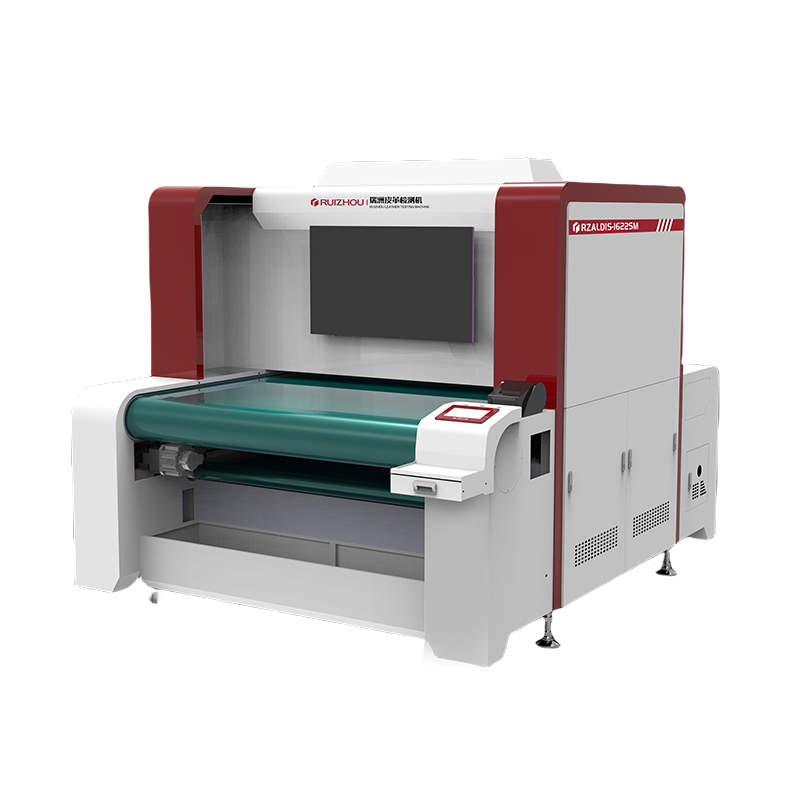

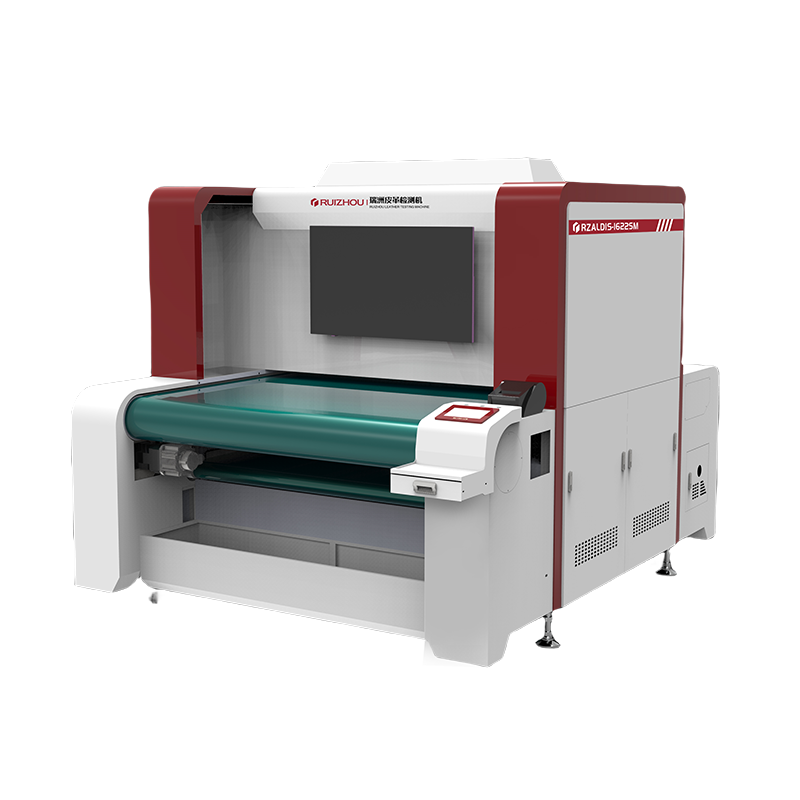

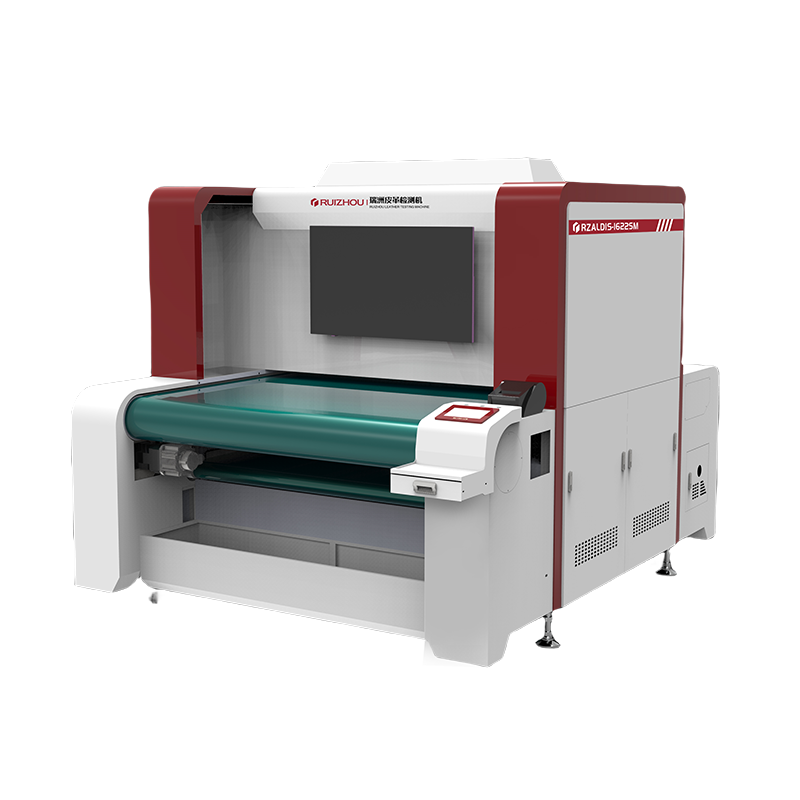

RZALDIS-1622SM is a machine for leather defects inspectation.

This scanner is a quality control solution that automatically detects defects in leather with high efficiency and accuracy.

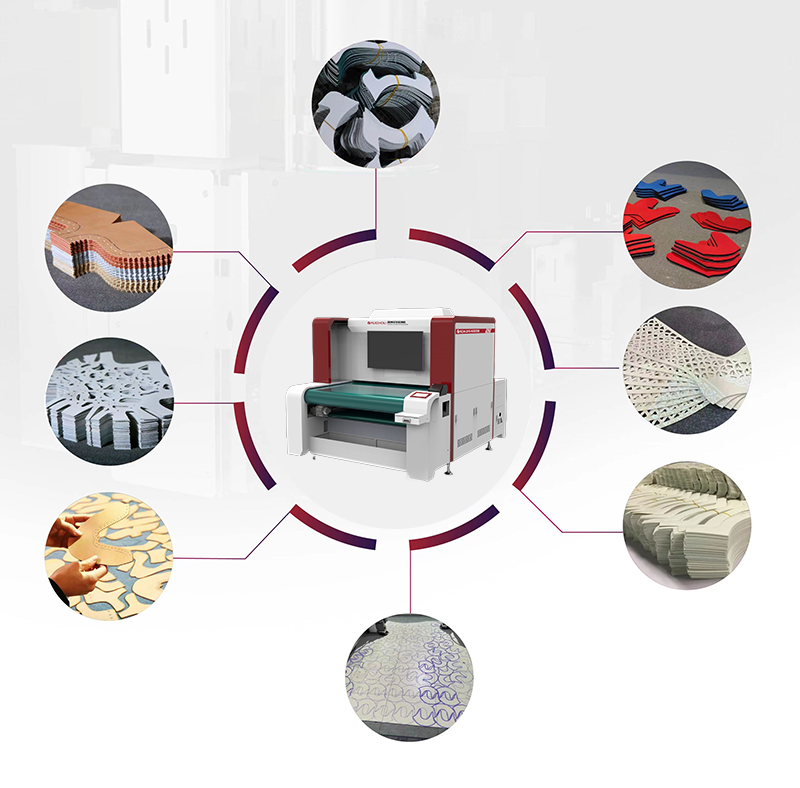

It is a valuable tool for leather manufacturers and retailers who want to improve the quality of their products and reduce waste. Now it’s widely used in many industries, like leather shoes, leather bags, automobile interior, etc

1. Major Features:

Leather Defects Scanner is an intelligent machine for quality control solution that automatically detects defects in leather products with high efficiency and accuracy. It uses a variety of sensors and algorithms to identify a wide range of defects, including scratches, blemishes, discolorations, and holes.

2. 4 Significant values make it stand in the lead!

With HD line-scan cameras, the horizontal resolutionreaches 30,000 pixels.

Different leathers and colors can be scanned, including cowhide, goat leather, pig leather, calf leather, etc. After scanning, the cutting files can be nested in the outline of the scanned leather.

Scanning time: about 40s/pcs.(1.8m x 1.8m)

Nesting time: about 2min/pcs.(1.8m x 1.8m)

Data management and review: the scanned results can be stored and checked anytime.

The original scanned images, defects data, outline data of the leathers can be calculated and exported daily or monthly.

3. TECHNICAL SPECIFICATION:

Model | RZALDIS-1622SM |

Effective Work Size | 1600(L)*2200(W)mm |

Applicable Material | Genuine Leather |

Defects | Open wounds, livestock brandingwormhole, ringworm scars |

Voltage | 7.5 kW |