In today’s fast-changing leather manufacturing industry, one question resonates with every producer: Is Intelligent Leather CNC Cutting Machine the future? With global demand for higher efficiency, sustainable production, and precise craftsmanship, the answer seems clear. The rapid rise of the leather cutting cnc machine is reshaping how companies approach production, offering advantages far beyond traditional cutting methods.

Breaking Away from Traditional Methods

For decades, manual cutting or semi-automatic methods dominated leather processing. These methods relied heavily on skilled workers, leading to inconsistent results, material waste, and limited scalability. As global labor costs increase and consumer demand for quality grows, manufacturers began searching for better solutions. That is where the cnc cutter for leather entered the picture. With automated control, intelligent software, and unparalleled accuracy, this machine is quickly becoming the cornerstone of modern leather production.

Why Intelligent Leather Cutting CNC Matters

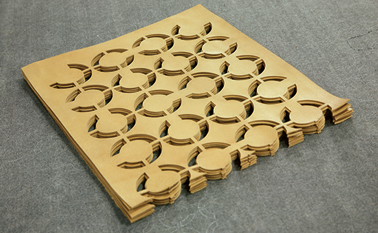

An intelligent leather cutting cnc machine combines high precision with advanced automation. Unlike traditional equipment, it uses computer-controlled systems and AI nesting software to optimize every cut. This means material waste is significantly reduced, saving costs and increasing sustainability. At the same time, the machine guarantees consistent results across thousands of pieces, making it invaluable for industries where precision is non-negotiable.

Manufacturers now rely on a leather cnc cutting machine not only to save labor but also to achieve levels of productivity that were previously impossible. From shoes and furniture to automotive interiors and luxury leather goods, intelligent cutting ensures that businesses remain competitive in a market where quality and efficiency decide success.

The latest generation of cnc leather cutting machine comes with innovative features that redefine industry standards:

AI Nesting Technology – The machine automatically arranges patterns to maximize material usage.

High-Speed Multi-Layer Cutting – Capable of processing multiple sheets simultaneously without losing accuracy.

Automatic Feeding System – Streamlines workflow and reduces downtime.

Smart Control Panel – User-friendly interface that minimizes operator training and errors.

Versatile Applications – Works with natural leather, synthetic leather, PU, PVC, and more.

These advantages not only improve efficiency but also allow manufacturers to respond faster to market changes, new designs, and customer demands.

Real-World Applications

Consider a footwear manufacturer struggling with rising material costs and inconsistent quality due to manual cutting. After adopting a leather cutting cnc machine, the company reported up to 15% savings in leather consumption and a 30% increase in output. Similarly, automotive interior suppliers rely on a cnc cutter for leather to meet strict international standards for car seats, dashboards, and trims, ensuring flawless precision with every cut.

Luxury brands in handbags and accessories also value the leather cutting cnc because it maintains uniformity across hundreds of pieces while handling delicate materials with care. This balance of speed, quality, and reliability is why so many industries are shifting toward intelligent solutions.

The global manufacturing landscape is moving rapidly toward Industry 4.0, and leather processing is no exception. The leather cnc cutting machine is not just a piece of equipment; it represents a major step toward smart factories, where data, automation, and AI work together to create efficiency and sustainability.

For manufacturers, investing in a cnc leather cutting machine means preparing for the future. It ensures competitiveness by lowering costs, improving productivity, and delivering higher-quality products. More importantly, it positions companies as innovators in an industry that is constantly evolving.

Is the intelligent leather cutting cnc machine really the future? The evidence suggests that it is not only the future but already the present. As more industries embrace automation and intelligent solutions, reliance on outdated cutting methods will continue to decline. The companies that adopt advanced leather cnc cutting machine technologies now will have a clear advantage in market share, efficiency, and customer satisfaction.

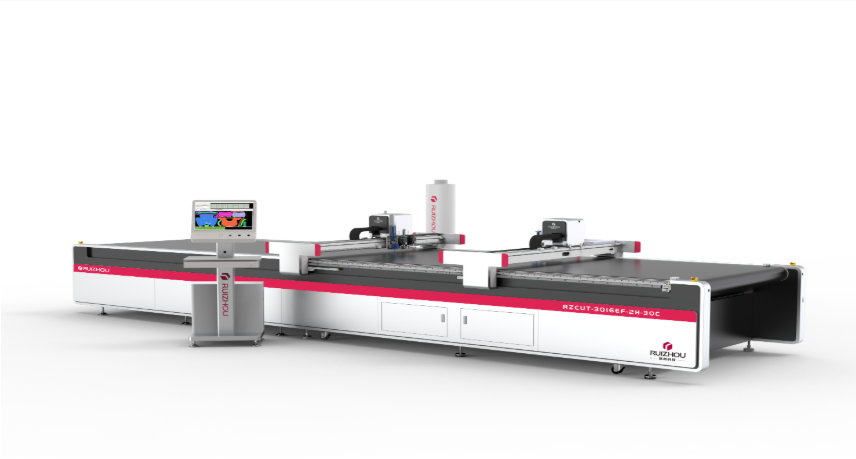

At Guangdong RUIZHOU Technology Co., Ltd., years of research and development have resulted in a new generation of intelligent cnc leather cutting machines that are transforming leather production worldwide. With global partnerships and continuous innovation, we are proud to provide solutions that redefine what is possible in leather cutting.

How to contact us?

The shift toward intelligent manufacturing is unstoppable, and the intelligent leather cnc cutting machine is at the center of this revolution. From precision and cost savings to sustainability and scalability, it provides everything modern industries demand.For businesses wondering if this is the right time to invest, the answer is clear: the future has already begun, and the intelligent cnc cutter for leather is leading the way.

👉 Learn more about our solutions at www.ruizhoutech.com and discover how the latest leather cutting cnc machine can transform your production.