Leather has always been one of the most valuable and challenging materials in the fashion, automotive, and upholstery industries. Its natural durability, texture, and aesthetic make it ideal for high-end shoes, handbags, furniture, and accessories. However, many manufacturers still face a common problem: how to cut leather without fraying and maintain a flawless finish while increasing efficiency. At Fiera Milano, Hall 10, Booth K47, September 23–25, 2025, RUIZHOU is presenting its most advanced solution — the automatic leather cutting machine that redefines precision and productivity.

The Challenge of Leather Cutting

Unlike textiles, leather does not have woven threads, but poor cutting methods can still create rough edges, uneven surfaces, or even waste valuable material. Traditional manual cutting often results in inconsistent accuracy, slow production, and material loss. Even outdated machinery can lead to fraying-like edges that damage the look and quality of the finished product.For companies in shoes, bags, belts, automotive interiors, and furniture manufacturing, these issues directly affect profitability and customer satisfaction. That is why upgrading to an advanced leather cutting CNC machine has become an urgent priority for factories aiming to stay competitive.

Introducing RUIZHOU’s Automatic Leather Cutting Machine

At the ongoing exhibition in Milan, visitors can see firsthand how RUIZHOU’s automatic leather cutting machine provides smooth, clean edges and precision cutting every time. The machine is designed to handle genuine leather, synthetic leather, and various hides with zero fraying and maximum efficiency.

Key advantages include:

High Precision CNC Technology: The leather cutting CNC system ensures every cut follows the programmed path with millimeter accuracy. No more wasted materials or irregular edges.

Versatility: Whether a factory needs a small leather cutting machine for prototyping or mass production with a large-scale leather cutting CNC machine, RUIZHOU offers flexible solutions to match different business sizes.

Efficiency Boost: Intelligent nesting software reduces material waste by arranging patterns in the most efficient way. This feature alone can save manufacturers up to 20% in raw material costs.

Automation & Labor Savings: The machine requires minimal manual intervention, reducing labor dependency while increasing consistency in production quality.

Durability: Built for 24/7 operation, the system is highly reliable and designed to withstand long-term industrial use.

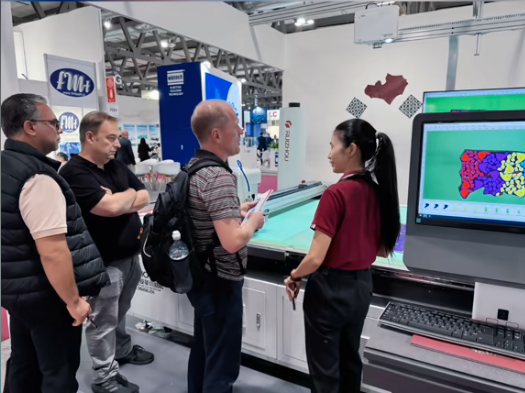

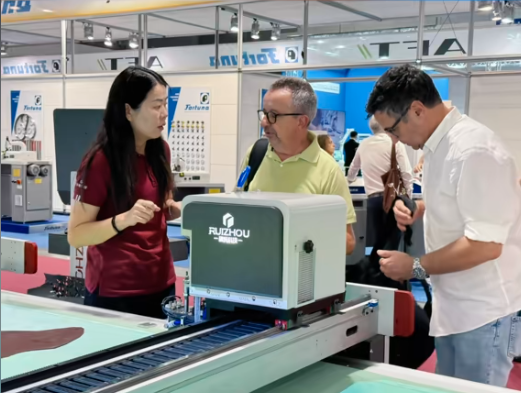

Why visit RUIZHOU at Fiera Milano? The exhibition is more than just a showcase — it is a live demonstration of how innovation is transforming the future of leather processing. At Hall 10, Booth K47, visitors can witness automatic leather cutting machines running at full speed, interact with engineers to understand how leather cutting CNC technology works in real-world applications, and see side-by-side comparisons that highlight the superior precision and cleanliness of cuts compared to traditional methods. The booth also provides expert guidance on selecting the right solution, whether it’s a small leather cutting machine for small-batch production or a high-capacity leather cutting CNC machine designed for industrial-scale output.

Exhibition site

Exhibition site

Exhibition site

Beyond Cutting: Smart Manufacturing

RUIZHOU’s commitment goes beyond just cutting leather. With advanced software integration, the leather cutting CNC machine supports intelligent production workflows. Digital designs can be imported directly into the system, reducing errors and accelerating time-to-market. AR projection and smart scanning can also be added to enhance accuracy and usability.This aligns with global industry trends where automation, digitalization, and sustainability are the key drivers of competitiveness. By reducing waste, improving energy efficiency, and optimizing labor, RUIZHOU’s technology is not only solving the challenge of cutting leather without fraying but also helping manufacturers build sustainable and profitable operations.

Who Should Attend?

This showcase is ideal for:

1

Footwear Manufacturers seeking faster, cleaner cutting of genuine leather for shoes.

2

Handbag & Accessories Brands that require intricate, precise patterns with zero fraying.

3

Automotive Interior Suppliers producing leather seats, steering wheel covers, and trim with consistent high quality.

4

Startups and Workshops that may begin with a small leather cutting machine but want scalability for future growth.

Why choose RUIZHOU? As a global leader in leather cutting CNC innovation, RUIZHOU has become a trusted partner for manufacturers in footwear, handbags, automotive interiors, and furniture. We continuously invest in R&D to ensure every leather cutting CNC machine stays at the forefront of industry technology. With dedicated after-sales support and professional training, we help clients quickly improve production efficiency and competitiveness. RUIZHOU also actively participates in international exhibitions such as CIMSA and Fiera Milano, showcasing the latest automatic leather cutting machine technology and applications, solidifying its leadership in the automated cutting sector.

Visit Us Today

The exhibition is happening now — don’t miss this opportunity to see the future of leather cutting. Visit RUIZHOU at Fiera Milano, Hall 10, Booth K47, September 23–25, 2025.

Learn more about our full range of automatic leather cutting machines and other cutting solutions by visiting our official website: www.ruizhoutech.com