In today’s fast-paced packaging industry, the need for precision, efficiency, and sustainability has never been more critical. Traditional cutting methods often result in excessive material waste, uneven edges, and longer turnaround times. That’s why more businesses are now turning to intelligent solutions like the CNC corrugated cardboard cutter — a game-changing technology designed to deliver flawless edges with zero waste.

The Evolution of Corrugated Cardboard Cutting

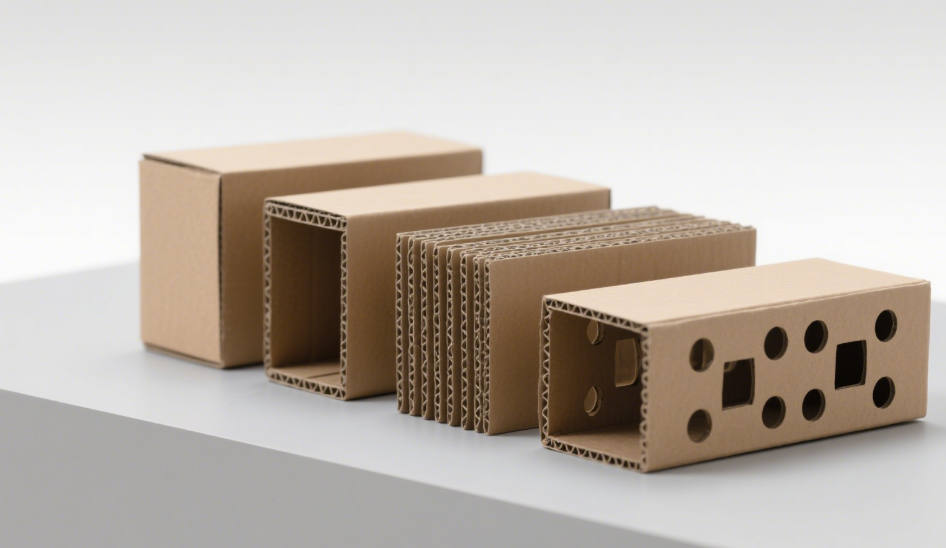

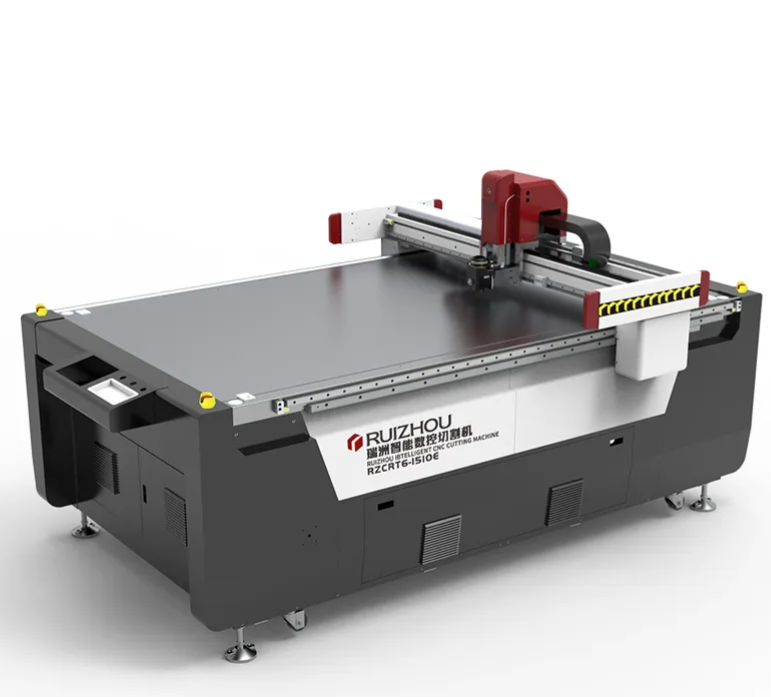

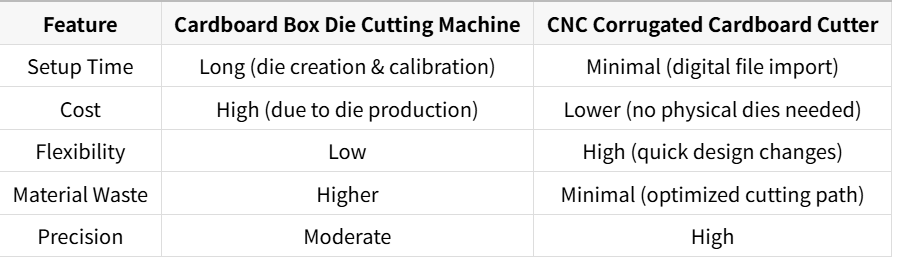

For years, packaging manufacturers have relied on conventional tools such as the cardboard box die cutting machine. While effective in high-volume operations, these machines require costly dies, lengthy setup times, and offer limited flexibility for custom or short-run jobs. In contrast, modern CNC corrugated cardboard cutters eliminate the need for dies entirely, using digital files and precision motors to make highly accurate cuts at any quantity.

This advancement not only saves time and money but also enables packaging companies to respond faster to custom orders, reduce material waste, and maintain superior quality with every cut.

In packaging, the quality of edges speaks volumes about the brand and product. Poorly cut boxes can compromise structural integrity, affect product protection, and diminish the unboxing experience. A CNC corrugated cardboard cutter guarantees sharp, smooth edges, which help improve box strength, aesthetics, and customer satisfaction. It’s a crucial upgrade for any business aiming to enhance brand presentation while streamlining production.

Zero Waste = Sustainable Advantage

Sustainability is more than just a trend — it's an industry standard. By reducing offcuts and optimizing material layout through intelligent nesting algorithms, a CNC corrugated cardboard cutter helps minimize raw material usage. This not only contributes to greener manufacturing practices but also significantly cuts down on costs.

When compared to traditional cardboard box die cutting machines, CNC systems provide a clear environmental and economic advantage. By eliminating the need for physical dies and making precision cuts from digital files, manufacturers can reduce their carbon footprint while delivering faster turnaround times.

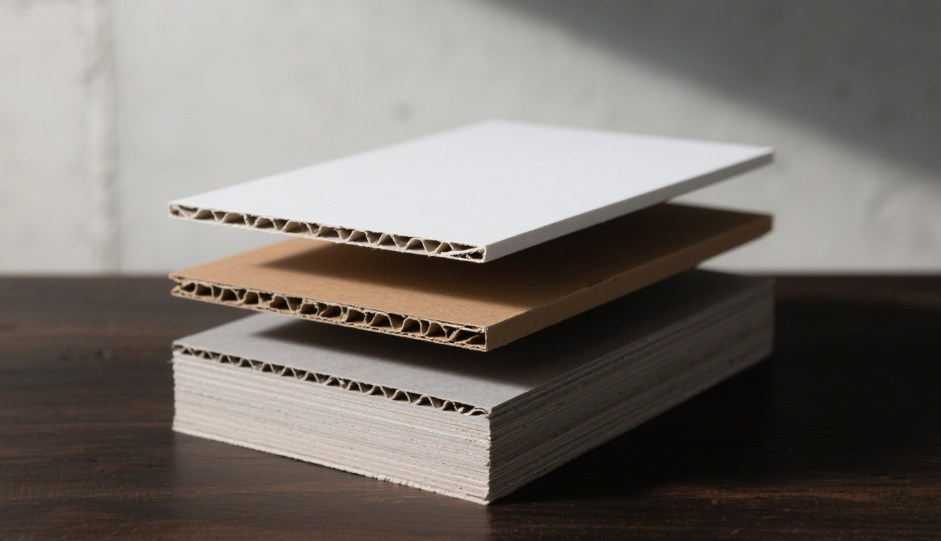

Our system doesn’t just cut — it thinks. As an advanced packaging machine cutter, it integrates seamlessly into your digital workflow. Whether you’re creating protective inserts, retail displays, custom shipping boxes, or prototypes, the machine adapts to various board thicknesses and designs with ease.

This versatility makes it the ideal solution for businesses handling diverse packaging needs. From bulk orders to on-demand production, the CNC corrugated cardboard cutter ensures speed, quality, and cost-efficiency at every stage.

Versatile Applications Across Industries

As a high-performance packing cutting machine, this equipment is used across multiple industries:

E-commerce & Retail – Custom boxes tailored to product dimensions.

Logistics – Optimized packaging for shipping efficiency.

Electronics – Protective cardboard inserts with intricate patterns.

Design & Prototyping – On-demand box samples without tooling delays.

No matter the industry, the need for flexible and reliable solutions like the corrugated board cutting machine is growing rapidly.

Comparing Traditional and Digital Cutting Solutions

This comparison highlights the clear benefits of upgrading to a CNC-based solution, especially for businesses seeking growth, customization, and sustainability.

Incorporating a CNC corrugated cardboard cutter into your production line is more than just adopting a new machine — it’s embracing a future-ready manufacturing model. It aligns with modern business goals: flexibility, low waste, faster delivery, and superior quality.

Whether you're looking to replace outdated cardboard box die cutting machines, streamline production with a packaging machine cutter, or scale your output using a fully automated packing cutting machine, our CNC solution is built to meet your needs.

Engineered for accuracy and designed for modern workflows, it also functions as a smart corrugated board cutting machine—capable of handling both mass production and short-run customizations without missing a beat.

In a world where packaging quality, speed, and environmental responsibility are all non-negotiable, the CNC corrugated cardboard cutter stands out as the tool that delivers it all. From flawless edges to zero waste, this intelligent cutting system offers unmatched advantages over traditional methods.

If your business is ready to upgrade its packaging workflow and meet the demands of today’s fast-evolving market, now is the time to make the switch.