As global manufacturing continues to evolve toward customization, digitalization, and fast turnaround, production equipment is expected to do far more than a single task. Manufacturers across apparel, electronics, footwear, and packaging are increasingly asking whether one cutting solution can truly deliver stable, high-quality results across different materials and applications. This Multi-material CNC cutting machine demonstrates that such versatility is not only possible, but practical for modern industrial production.

Developed by an experienced CNC cutting machine manufacturer, this system integrates high-speed motion control, intelligent nesting software, and industrial-grade mechanical design. It is engineered to process a wide range of flexible and semi-rigid materials with consistent cutting accuracy, ensuring smooth edges, precise contours, and minimal deformation. By maintaining cutting stability across different thicknesses and material densities, the machine significantly reduces rework and material waste, allowing manufacturers to move directly into downstream production stages.

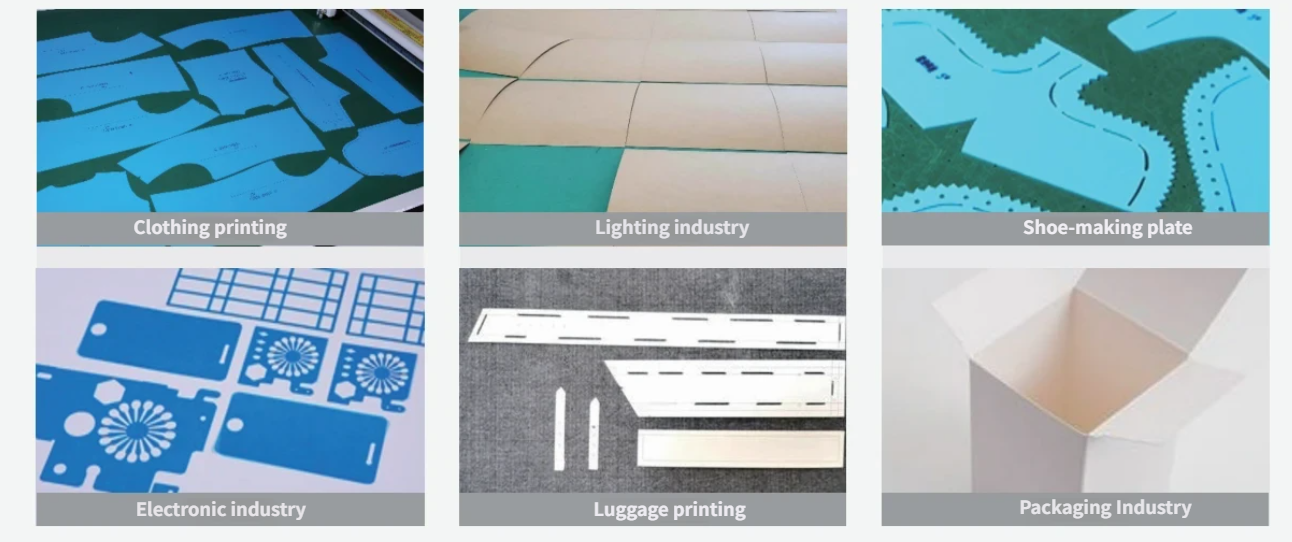

Precision Cutting Performance Across Diverse Industries

In garment pattern making, cutting precision directly impacts fit accuracy and fabric utilization. This CNC system delivers clean, continuous edges on woven fabrics, knitted textiles, and technical materials used in apparel production. During both sampling and bulk manufacturing, the machine ensures that digital patterns are reproduced accurately, improving consistency between batches and accelerating response to fashion trends. The smooth cutting finish minimizes fraying, which enhances sewing efficiency and final garment quality.Within the electronics industry, material protection and dimensional precision are essential. The machine handles insulation materials, protective films, and flexible substrates with controlled cutting force, preventing edge tearing or surface damage. Its precise tool control ensures that electronic-related components maintain structural integrity, supporting high standards required in electronic product assembly and enclosure manufacturing.

For the lighting industry, where both functional accuracy and visual appearance are critical, the machine produces sharp, smooth edges on plastic sheets, decorative panels, and layered materials. Complex curves and customized shapes are cut accurately, ensuring that lighting components fit perfectly during assembly while maintaining a refined surface finish that enhances the final product’s aesthetic value.In bag and luggage pattern development, materials such as leather, synthetic leather, foam padding, and reinforcement boards require both precision and consistency. This CNC cutting solution ensures clean separation and accurate alignment of each component, resulting in neatly finished edges that support efficient stitching and assembly. Reliable pattern repeatability allows manufacturers to scale production without sacrificing craftsmanship, meeting both premium customization and mass-market demands.Footwear pattern making places high demands on cutting accuracy due to the combination of uppers, linings, midsole boards, and composite layers. The machine delivers stable depth control and precise contour cutting, ensuring that each footwear component fits seamlessly in subsequent bonding and molding processes. Improved cutting accuracy enhances shoe comfort, durability, and overall production efficiency.In the packaging industry, efficiency and material optimization are key drivers. The machine cuts cardboard, corrugated board, and composite packaging materials with clean edges and accurate crease lines. This precision improves box strength, folding accuracy, and overall packaging quality while reducing material waste. Rapid switching between different packaging designs enables manufacturers to meet diverse customer requirements with minimal downtime.

Industrial Reliability and Long-Term Production Value

Beyond its application flexibility, this machine is built for continuous industrial operation. As a trusted Industrial CNC cutting machine supplier, the manufacturer has focused on structural stability, intelligent control systems, and long-term durability. The machine is widely adopted as a CNC cutting machine for automotive interiors, where consistent quality is essential for seat fabrics, interior trims, and soundproofing materials. Its performance as a CNC cutting machine for composite materials further demonstrates its capability to handle demanding applications that require both strength and precision.By consolidating multiple cutting tasks into a single system, this solution reduces equipment investment, simplifies production workflows, and enhances operational flexibility. Manufacturers benefit from improved productivity, stable quality output, and the ability to adapt quickly to new materials and market demands.This Multi-material CNC cutting machine proves that one well-designed system can indeed handle multiple materials perfectly. It offers a practical, future-ready solution for manufacturers seeking accuracy, efficiency, and long-term competitiveness in an increasingly complex industrial environment.

For more information about this product and complete CNC cutting solutions, please visit:www.ruizhoutech.com